Shop Floating Shelves

Shop

-

43″ Heavy Duty Floating Shelf Bracket

$64.99 -

32″ Heavy Duty Floating Shelf Bracket

$52.50 -

Floating Shelf Bracket DIY Drill Guide Kit

$49.99 -

Router Guide Kit

$39.99 -

Super Duty Floating Desk Bracket

$39.99 -

24″ Heavy Duty Floating Shelf Bracket

$39.99 -

18″ Heavy Duty Floating Shelf Bracket

$38.95 -

12″ Heavy Duty Floating Shelf Bracket

$37.99 -

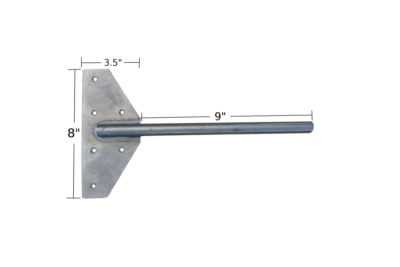

Super Duty Floating Shelf Bracket

$37.00 -

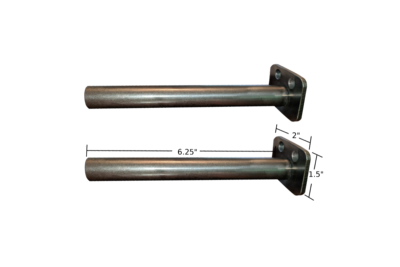

2″ Heavy Duty Floating Shelf Bracket Pair

$30.00